Dumbwaiter

Client

Project type

Freelance

Product design

Technical development

Manufacturing

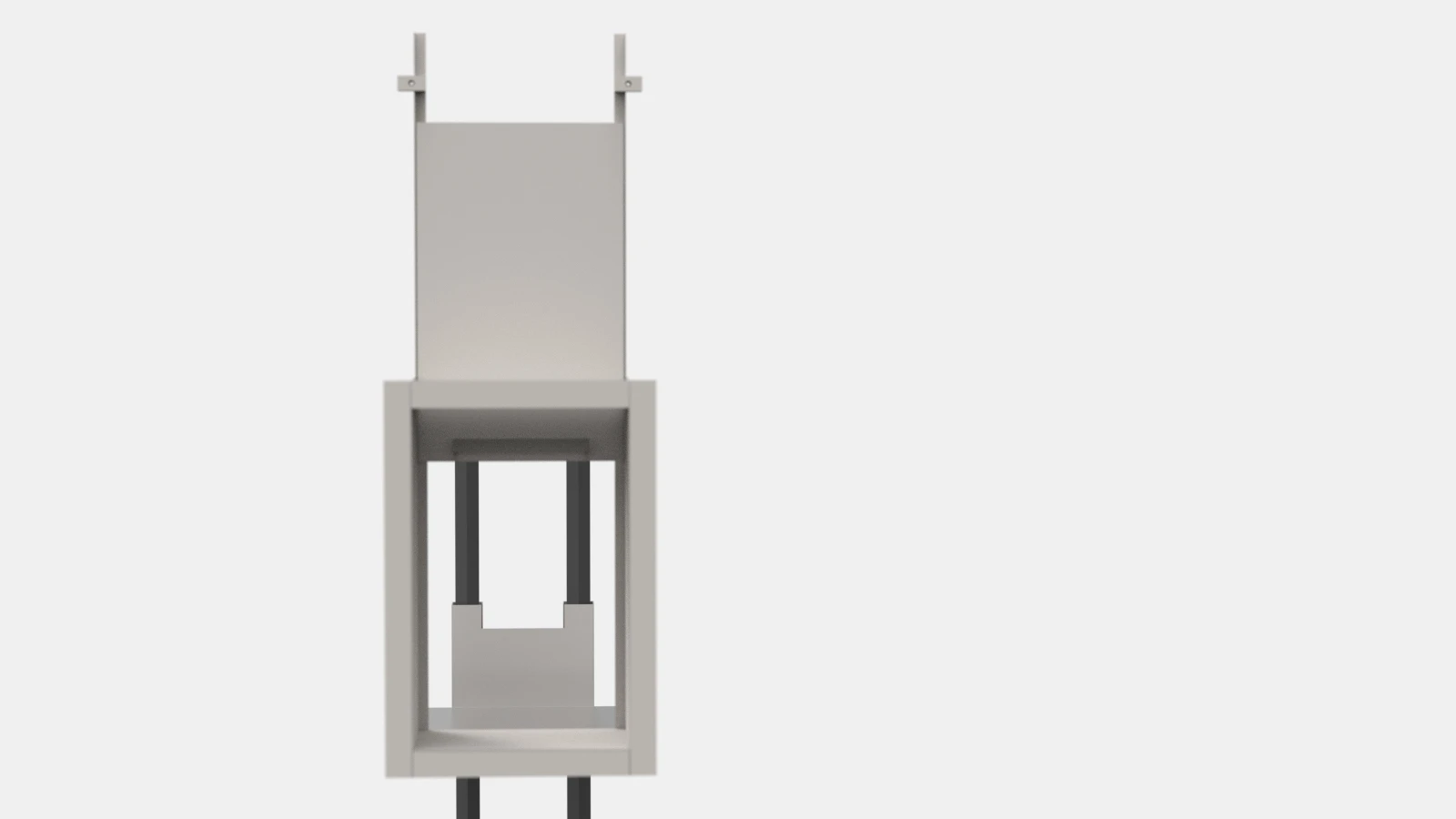

Electro-mechanical device for lifting small loads (max 70kg.) for the home. Total route 4.60m.

Brief:Move small loads vertically, from ground floor to upper floor, with a restricted horizontal surface. This was the biggest determining factor when it came to the technical resolution, along with the smaller space needed to house the motor, rail system, cables and pulleys.

A "traditional" scheme for moving industrial forklifts could not be applied since it took away a lot of surface area on the transport car.

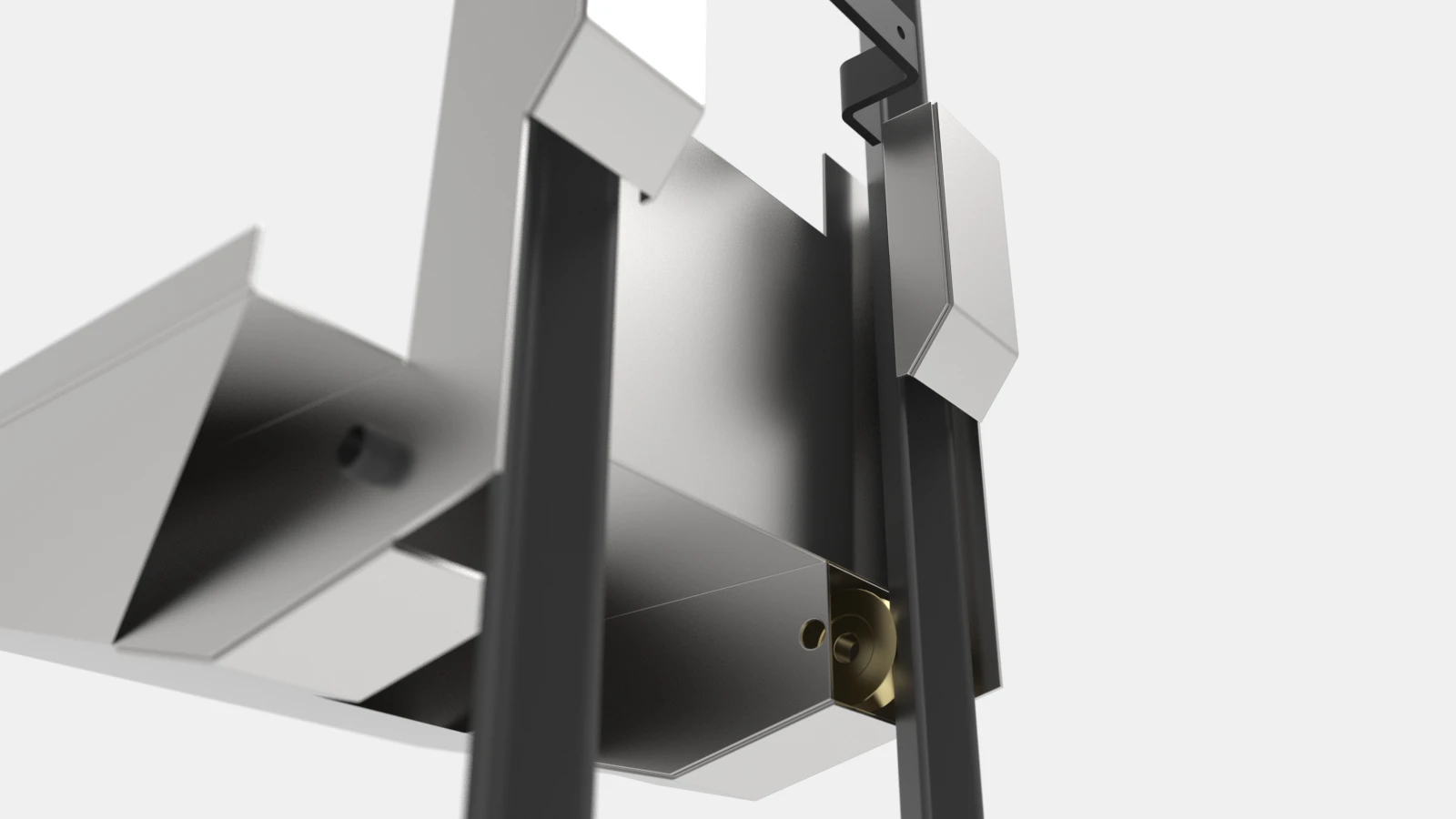

A bi-rail system adjacent to the wall was chosen, which thanks to the leverage effect and gravity, supports two skates and two wheels on each of them. In this way, wasting space essential for optimal operation was avoided.

Another key aspect to take into account during development was the modularity of the rails, both for transportation and installation. Taking into account that after being installed, they must be perfectly aligned.

La construcción de todo el sistema se realizó en materiales metálicos, asegurando una alta resistencia y durabilidad. Disminuyendo el mantenimiento, sin comprometer un funcionamiento amable al entorno domestico (minimas vibraciones y ruidos)

En relación a la interfase con el usuario, se planteó un sistema de control remoto dual (planta baja / alta) para una independencia total en el uso.

Towards the end of the tour on the upper floor, the process of opening/closing the sliding door was automated. The same conveyor cart hooks the lower part of the door, allowing it to be lifted. This system allows the hole located in the wall to be kept closed when the car is on the ground floor, thus avoiding possible accidents.